Production and quality inspection

Production overview

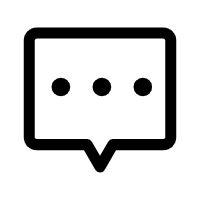

The "14th Five-Year Plan" and the 2035 Vision and Goals Outline clearly cultivate specialized, special and new "Little Giant A" enterprises and manufacturing single champion enterprises, becoming the main force of scientific and technological innovation and the backbone of China's economic development. Hangzhou Dayian Control Machine Tool Co., Ltd., as a manufacturer of high-end flexible composite machine tools and intelligent green and efficient machine tools, subdivided the field to fill the domestic blank products, declared a specialized, special and new "little giant" enterprise, and the production and procurement department as the company's value stream output department, carried out refined production management, vigorously promoted lean production, reduced defects, reduced rework, improved production efficiency, optimized lean supply chain, reduced production costs, and created greater value. And perennially hire senior lean consulting companies, digital construction companies based on product life cycle data interconnection to structure lean and information systems, continue to carry out lean production management, improve management processes, achieve the foundation of information value, and use information to promote management improvement, lean and information complement each other, to achieve the purpose of management upgrading and cost reduction and efficiency increase. The so-called lean thinking is to input less resources (refinement) and output greater results (benefits), from customer information collection to product delivery, the whole life cycle of fine management, manufacturing execution system (MES) to establish the correct value stream, ERP system to ensure the efficient and comprehensive flow of the production workshop, improve the quality of decision-making, budget, communication, planning, manufacturing, product quality, etc. Let quality as the benchmark of fine management, let efficiency as the task of fine management, and ultimately exchange the company's profits, cash flow and asset-liability ratio. Research and development of flexible composite machine tool production planning method and scheduling management Dayantian Control has also been exploring how to shift from "rigid production" to "flexible production" to meet the requirements of the buyer's market and customer personalization, customization, timeliness, etc., and has formulated a set of flexible production and flexible manufacturing to meet the "diversified, small-scale and controllable cycle", improve the lean supply chain, and improve the flexible response ability of production capacity, so that the company has the flexibility of survival and development and better contributes to social development. Research and development to form a new production mode with a high degree of integration of lean production and informatization The introduction of lean thinking achieves the foundation for the creation of information value, uses information to promote management improvement, continuously improves management processes, shows data benefits, clearly divides the overall planning of production scheduling and single production line scheduling, prudently determines the dimensions of product processes, reasonably controls the production structure, uses information to drive the company's overall management process system to sort out, improve, upgrade, informatize and then improve, upgrade, and informatize, so that management can be pulled and improved, thereby improving production efficiency, reducing abnormal problems, and reducing production costs.

Large day control quality inspection control system

The quality inspection of Dayan Control Machine Tool Co., Ltd. is divided into three parts: incoming material inspection, metal processing inspection, machine tool inspection, and key process inspection and control.

Incoming inspection

Incoming inspection ...

Machine tool inspection

Inspection and control of key processes

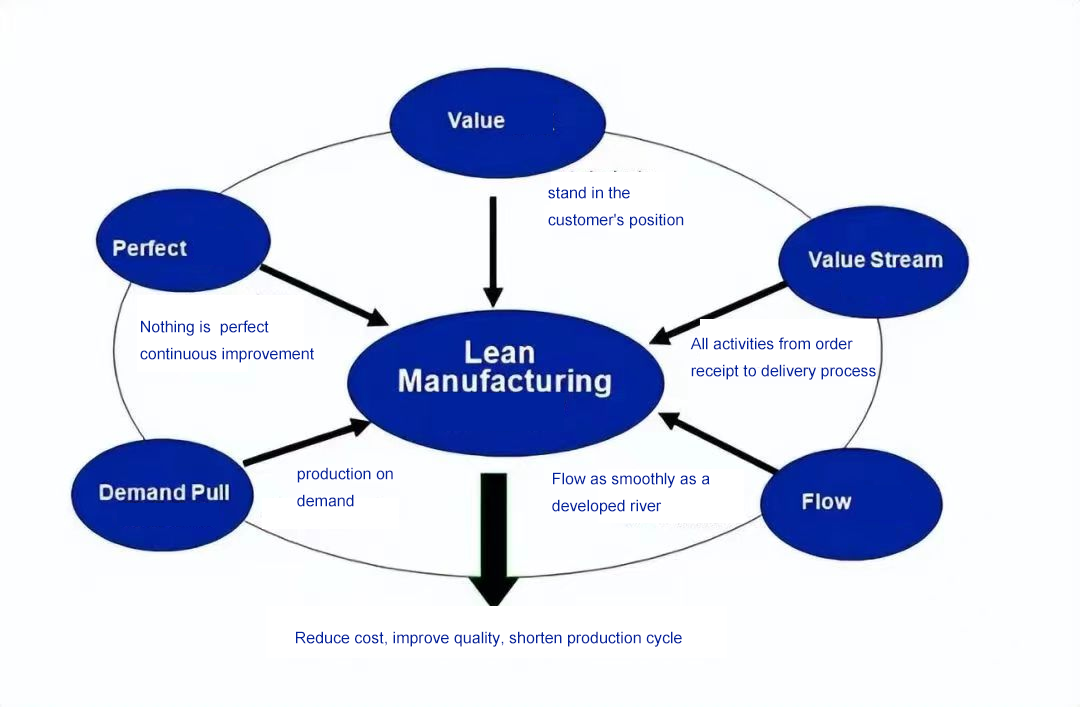

Incoming inspection is divided into class A, B, C according to the importance, class A, B substances in the company can not be inspected substances or items, the company according to the design standards, require the supplier to provide a test report, such as the CNC system supplier should be in accordance with the provisions of JB/T8832 to require the supplier to provide a test report; The casting supplier shall provide test reports in accordance with the provisions of GB/T 3997; Class A, B substances or the company that can be inspected by the project company compiles the original (auxiliary) material inspection procedures, spare parts inspection procedures, and the inspector inspects and records them according to the requirements of the regulations; The personnel of the Class C substance warehouse count the data, check the certificate of conformity, and if necessary, the inspectors participate.

Incoming inspection process: warehouse management personnel according to the delivery note to notify the inspector for inspection, the inspector according to the urgency of the incoming material to arrange the inspection order, qualified to fill in the inspection report for warehousing processing, unqualified fill in the unqualified product notice for return, selection, reuse, etc. and do a good job of marking processing, the reused product must have the general manager and above authority personnel agreed.

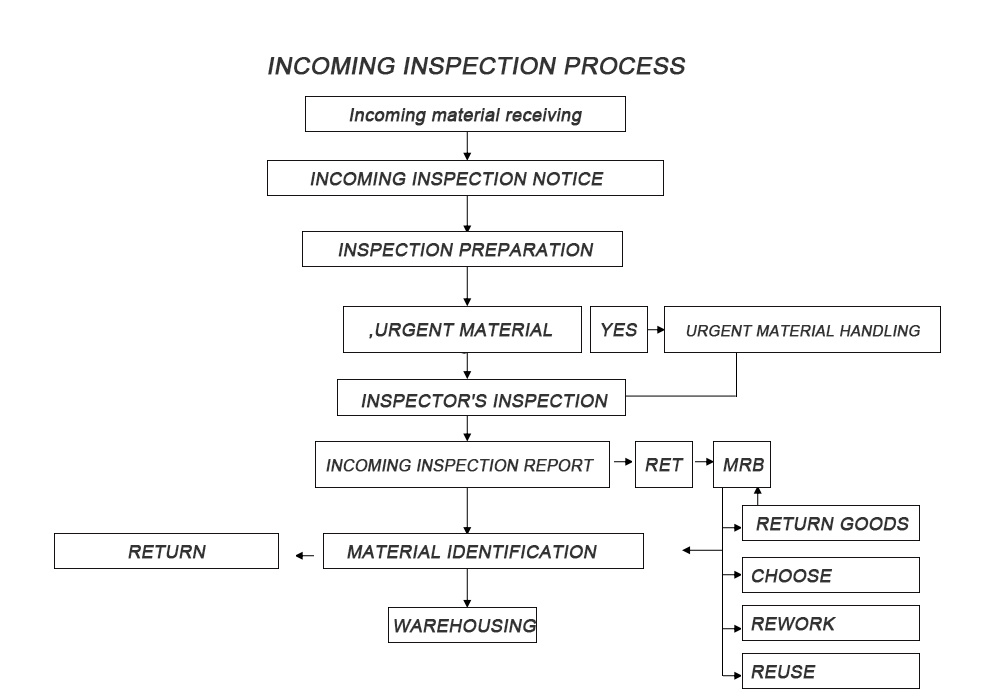

First inspection: when the operator processes the first product, the first self-inspection must be carried out, fill in the "process flow card" after qualified, and send it to inspection in the form of an inspection form, after the inspector passes the inspection, the first article can flow normally, and when the self-inspection is unqualified, it is necessary to analyze and find the reason, until the problem is solved and the qualified product is processed, and then send the inspector for the first article inspection, and the unqualified products should be reported to the inspector for identification and isolation. After the operator sends the first inspection, the inspector should be in place as soon as possible, if the work task is urgent and cannot be inspected and confirmed in time, the worker is allowed to leave the first piece to be inspected by the inspector (except for the five major items, the on-the-job inspector must report to the quality assurance minister to arrange personnel for the first inspection), and then can produce normally; However, when the inspector fails the inspection, the operator must re-inspect all the products that have been produced. After the first article inspection is qualified, the operator can carry out continuous processing of products, and in strict accordance with the testing frequency requirements specified in the process documents for the specified items for spot check testing, when found to be unqualified, must immediately stop processing, according to the situation to the processed products for re-inspection, while analyzing and finding the reason, until the problem is solved and the qualified products are processed and then continuous processing. The inspector inspects and records the first product sent for inspection by the operator after passing the self-inspection, and seals or signs the test result for confirmation. After the first article is qualified, the processing can continue, and if the first article is unqualified, the inspector will notify the manufacturer of the measurement results to readjust, and then carry out the first article inspection after it is qualified.

If unqualified is found during the inspection, the producer should be notified in time to stop processing and make adjustments, continue processing after qualified, re-inspect all the products that have been produced, and isolate all unqualified products. In the process of inspection, the inspector should supervise the operator to conduct self-inspection and implement process discipline in accordance with the provisions of the process documents, and if a violation is found, it should be corrected in time, and feedback to the relevant management personnel and quality assurance director of the workshop. When the quality is abnormal, the frequency of detection should be increased, and inspection records and feedback should be made.

Completion inspection: When the parts complete a certain process, the inspector receives the inspection report from the operator or dispatcher according to the provisions of the process documents and inspection documents, and fills in the inspection report after passing the inspection; According to the emergency of the task, the inspection shall be completed within 2 days, and there shall be no delay in production. When abnormal quality is found, the inspection volume of the parts subject to sampling inspection should be increased, and all inspection should be carried out if necessary, and inspection records and feedback should be made.

When there are non-conforming products, it shall be implemented in accordance with the "Non-conforming Products Control Procedure", and make identification and quality records. Where the inspected products are inspected, the inspector shall mark and record the inspected products in accordance with the "Measures for the Management of Marking and Traceability" and "Record Control Procedures".

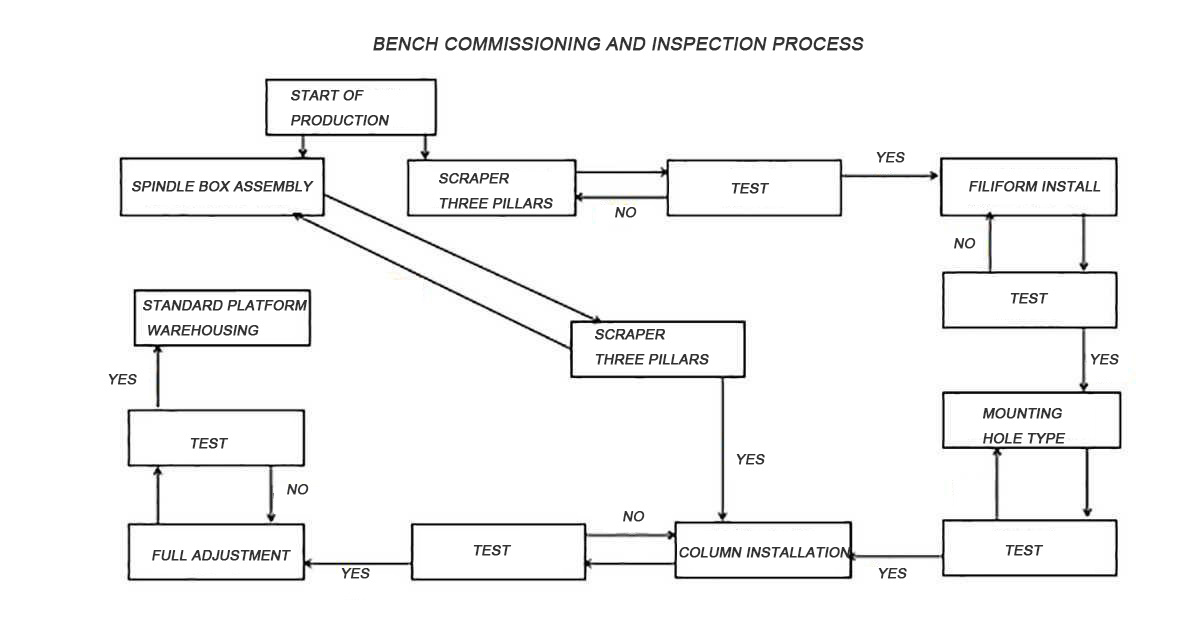

It can be divided into bench commissioning inspection and machine tool bench inspection

3.1. Quasi-table debugging inspection: spindle box assembly inspection, scraping inspection, screw assembly inspection, wire gauge installation inspection, assembly debugging inspection. All processes are fully inspected, and the inspector inspects and records them according to the "Machine Tool Assembly Operation Instructions" and "Machine Tool Assembly Inspection Regulations". Qualified flows into the next process, and if it is found that it is unqualified, fill in the "Nonconforming Product Notice/Examination Form", and the assembly personnel rework on site, and there is no concession problem. The quality assurance department conducts random inspection of each process according to the needs.

3.2. Inspection of finished machine tools

The sheet metal installation is independently inspected according to the "Machine Tool Assembly Operation Instructions"

The electrical installation is independently inspected according to the "Machine Tool Assembly Operation Instructions"

The tool magazine installation is independently inspected according to the "Machine Tool Assembly Operation Instructions"

The tool magazine running and closing inspection is recorded according to the "Machine Tool Assembly Operation Instructions"

The geometric accuracy inspection of machine tools is based on the inspection records of "Machine Tool Assembly Operation Instructions" and "Machine Tool History"

Laser interferometer inspection "laser operation instructions" and "machine tool history" inspection records

The working accuracy of the machine tool, according to the standard of "Precision Vertical Machining Center" made in Zhejiang, requires that each must be cut test, and the test piece is qualified by three-coordinate testing.

Machine tool leak test is recorded according to the "Machine Tool Assembly Operation Instructions"

The appearance and electrical inspection of machine tools are inspected and recorded according to the "Machine Tool Assembly Inspection Regulations", "Paint Inspection Regulations", "Sheet Metal Inspection Operation Instructions", "Machine Tool Assembly Operation Instructions" and "Machine Tool Appearance Inspection Standards". After passing the visual inspection, the machine tool label is affixed.

After the process inspection is qualified, it can flow into the next process, and if it is found to be unqualified, fill in the "Non-conforming Product Notice/Review Form", and the assembly personnel will rework on site, and there is no concession problem. After the inspection of each process of the machine tool is qualified, the quality assurance department will conduct a sampling inspection of important items, and the machine tool number will be stored after the sampling inspection is qualified, and the customer will accept the goods after acceptance.

The key process of Hangzhou Dayan Control Machine Tool Co., Ltd. is screw installation and wire gauge installation

4.1. The key process management personnel shall supervise the measuring instruments of the key processes to ensure that the effectiveness of the measuring instruments is within the verification cycle. If the situation is found, it should be reported to the quality assurance department in time. Before the use of key process detection instruments, operators and inspectors self-calibrate and self-inspect. The inspector performs daily supervision or helps the operator to calibrate and inspect.

4.2. Key process operators must be trained and can only take up their posts after passing the examination.

4.3. The operators of key processes must have self-inspection and records, and the inspectors shall inspect and record in strict accordance with the inspection guidance documents. The inspector supervises the implementation of the operator's process discipline: check the operator's self-inspection record and view the operator's self-made logo. If illegal operations are found, they should be discouraged in time, help to correct, and in serious cases, report to the quality assurance department and hand them over to the relevant departments for handling.

4.4. The quality assurance department is responsible for organizing the supervision and inspection of quality control points, organizing inspections once a month, filling in the record form, and reporting the inspection results to the comprehensive office for assessment.

Summary: The quality assurance department summarizes and analyzes quality problems every month, supervises the unqualified situation in the improvement process, and reports the performance appraisal of the comprehensive office for repeated problems.

Datan CNC's main products or services: high-speed and high-precision machining center, five-axis Simultaneously controllable machining center, functional complex machining center, flexible manufacturing units, Hardware, software and service providers for R&D and production of high-end and mid-to-high-end CNC machine tools.

Contact Details

E-mail:slash@hzdtsk.com

Address: Lin Pu high tech Development zone of xiaoshan District of Hangzhou city in Zhejiang province China