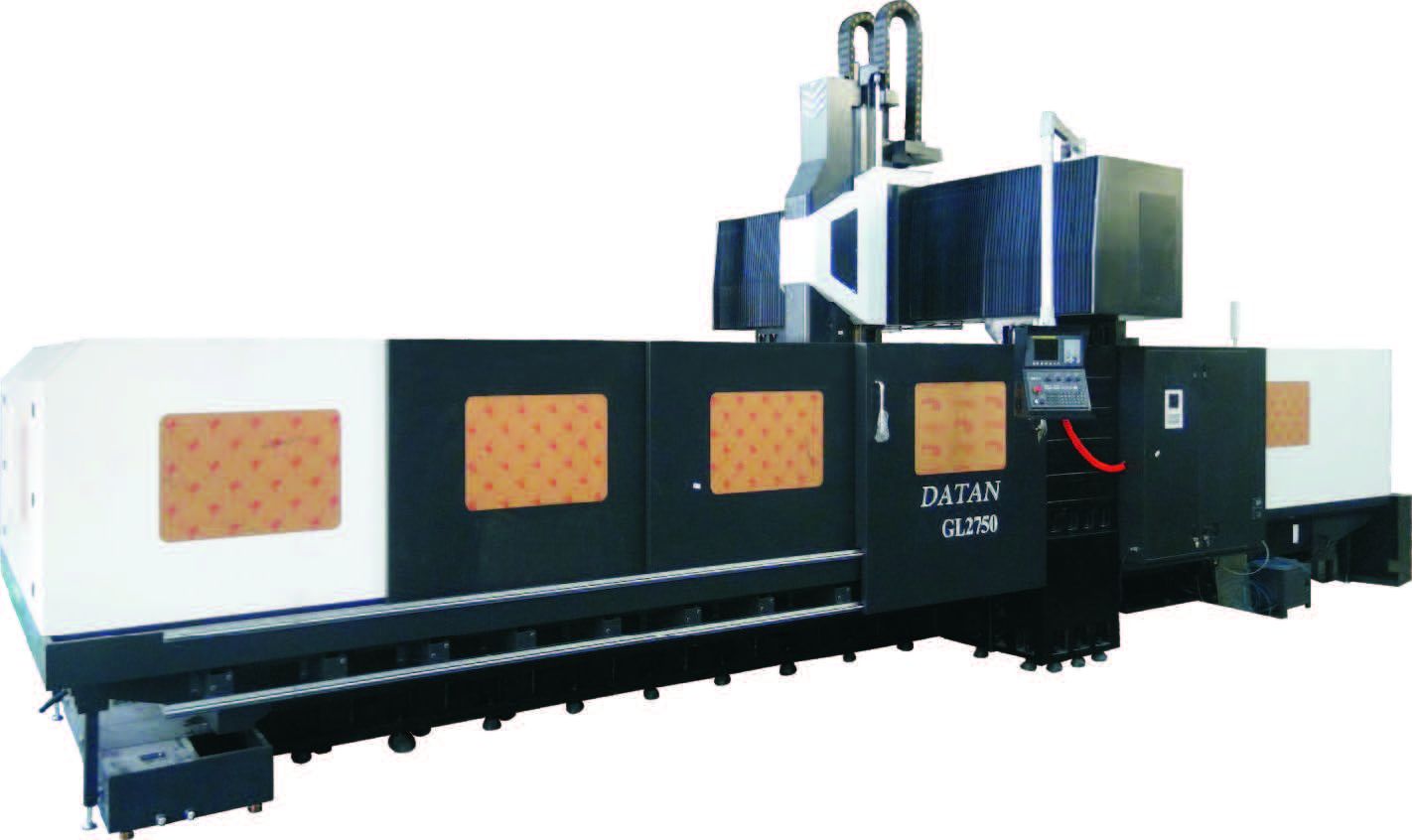

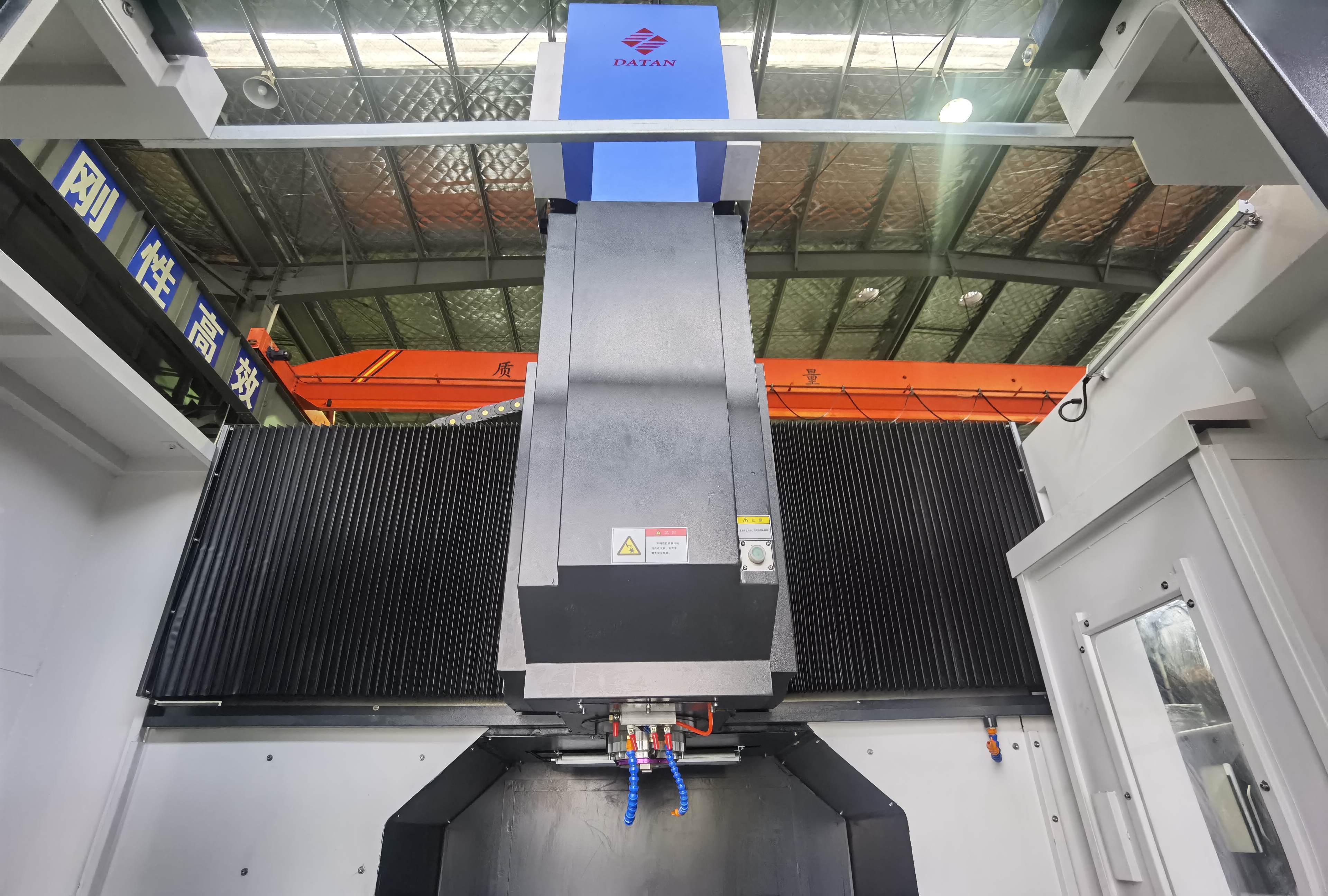

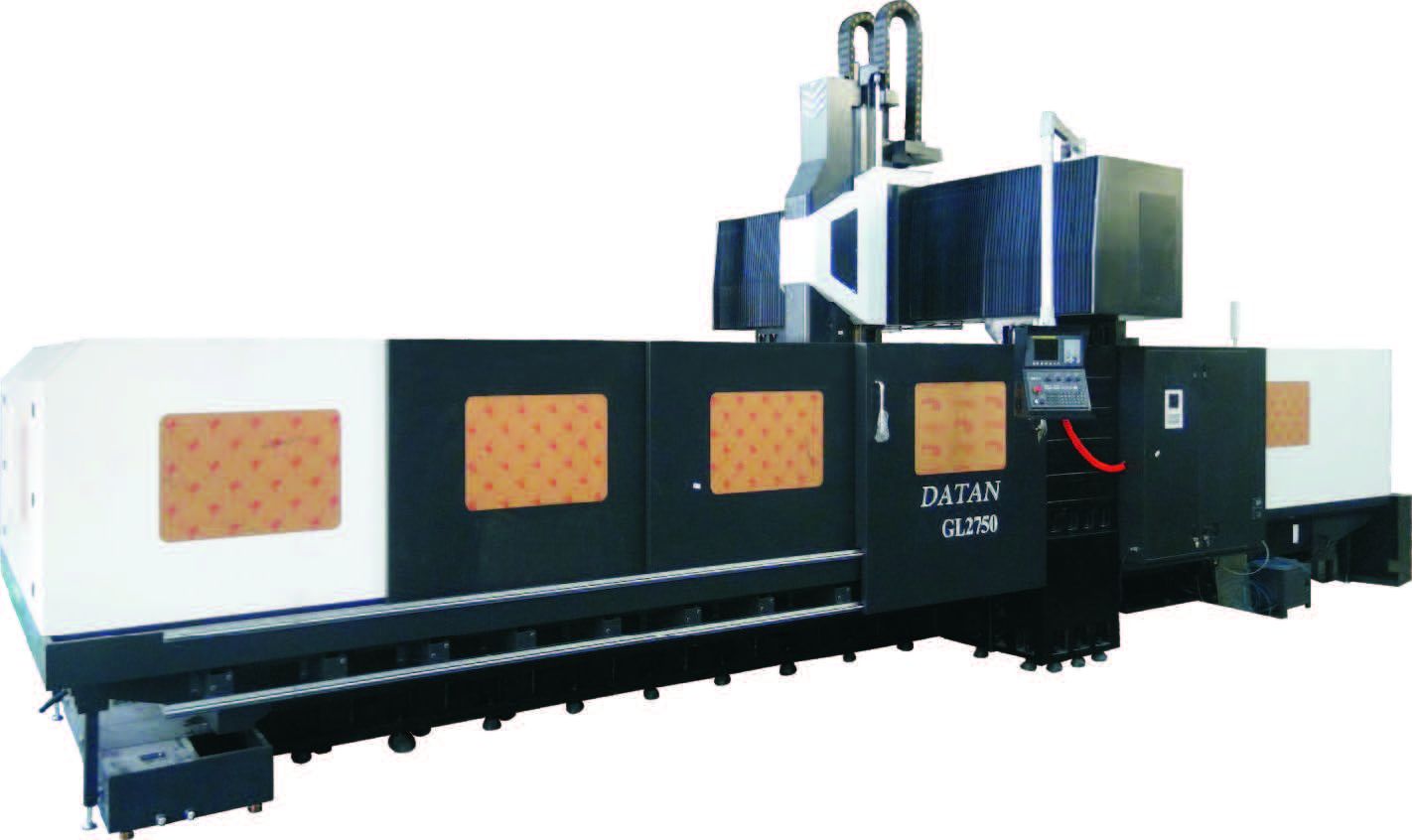

High rigid gantry machining center

GL6034

Workbench size: 6000 × 2600mm

Spindle speed: 6000r/min

CNC system: FANUC 0i mf plus of Japan

Keyword:

· Reasons to choose us ·

Excellent qualifications and abilities

DATAN CNC is a national high-tech enterprise, a national torch plan undertaking enterprise, and a national innovation fund undertaking enterprise; it has a high-efficiency composite R&D center in Zhejiang Province, and has undertaken three national-level scientific and technological projects and three provincial and municipal major scientific and technological projects in recent years. Possess dozens of patented technologies

Reliable product quality

The production and sales system is perfect, and the product quality is reliable. There is a professional marketing team and a perfect after-sales service system.

mailbox:tyler@hzdtsk.com

After-sales service is guaranteed

There are 18 technical service specialists: distributed in Shandong, Anhui, southern Jiangsu, northern Jiangsu, Shanghai, Wenzhou. Taizhou, Ningbo, Jinhua, Hangzhou and other 13 offices. Each technical service specialist is selected from all positions in the workshop and has at least 10 years of professional skills in machine tool debugging and electronic control. Moreover, the technical service specialists in Jiangsu, Zhejiang and Shanghai are equipped with special service cars to ensure service timeliness.

Sufficient production experience

Large day control: intelligent and efficient composite machine tool brand

The founder has 50 years of production technology accumulation, providing intelligent precision, high speed and high precision, powerful and efficient, five-axis linkage machine tools

mailbox:tyler@hzdtsk.com

- 产品介绍

-

- Commodity name: High rigid gantry machining center

- Commodity ID: GL6034

- 行程: >1600mm

- 主轴功率: 22/26kw

Three axis travel: 6200 × 400 × 1250mm<br> Workbench size: 6000 × 2600mm<br> Spindle speed: 6000r/min<br> CNC system: FANUC 0i mf plus of Japan

Specifications(Unit in brackets)

Travel

Left and right X axis - 6200 (mm), front and rear Y axis - 4000 (mm), upper and lower Z axis - 1250 (mm);

workbench

Size: - 6000x2600 (mm), maximum bearing: - 18000 (kg), distance from workbench to spindle end face: - 350 to 1600 (mm);

Feed drive

G01 feed speed 10 (m/min), G00 fast moving speed - 10 (m/min);

Spindle

Spindle taper BT50, spindle speed 6000 (rpm), spindle motor 22/26 (kw),

Triaxial

accuracy

Positioning accuracy 0.02, repeated positioning accuracy 0.015 Tool magazine

Robot tool magazine 24 (pcs), tool change time 1.8 (s), maximum tool length 300 (mm), maximum tool diameter 78 (mm), maximum tool diameter 120 (mm), maximum tool weight 8 (kg);

other

product details

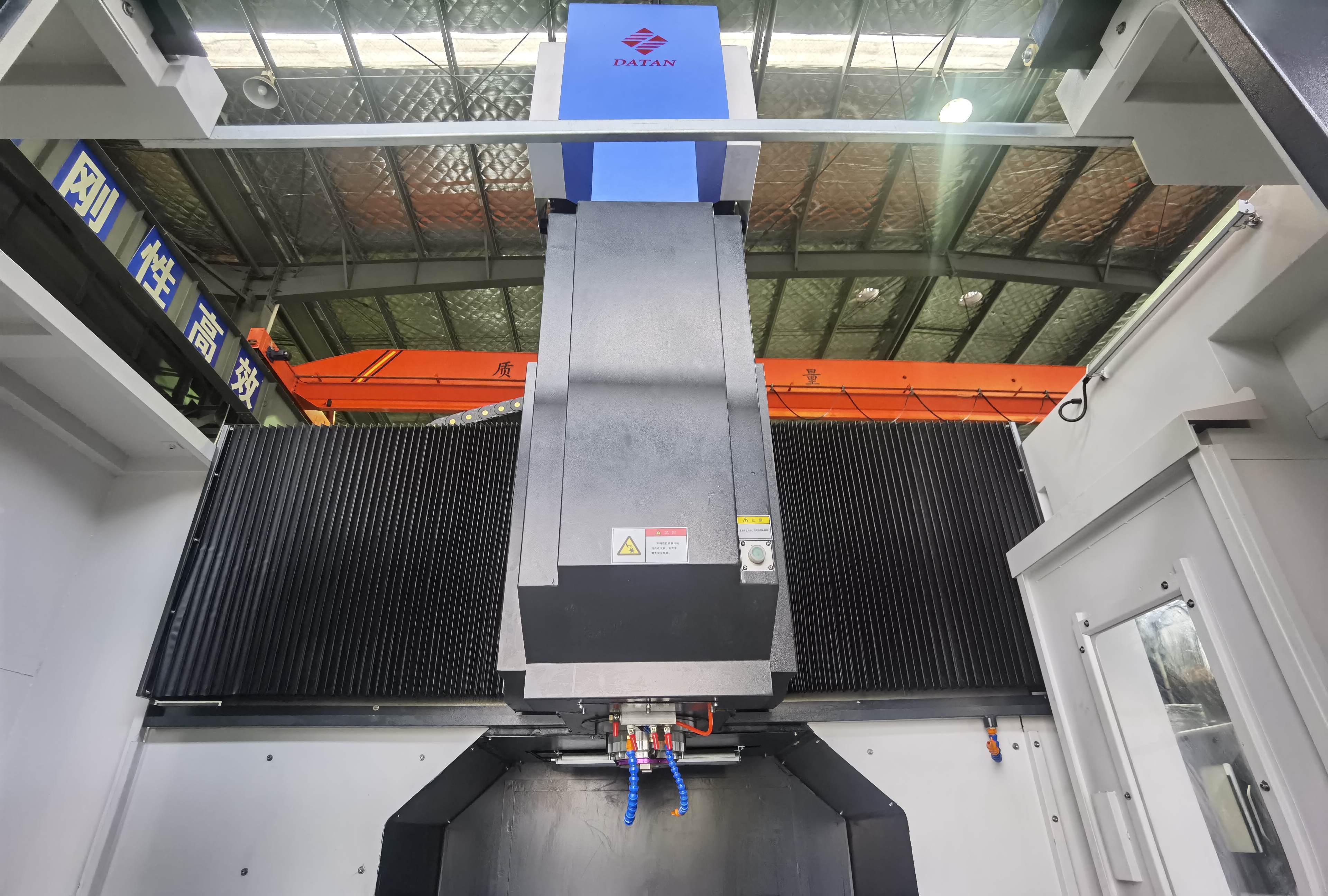

GL3460 high rigid gantry machining center

-

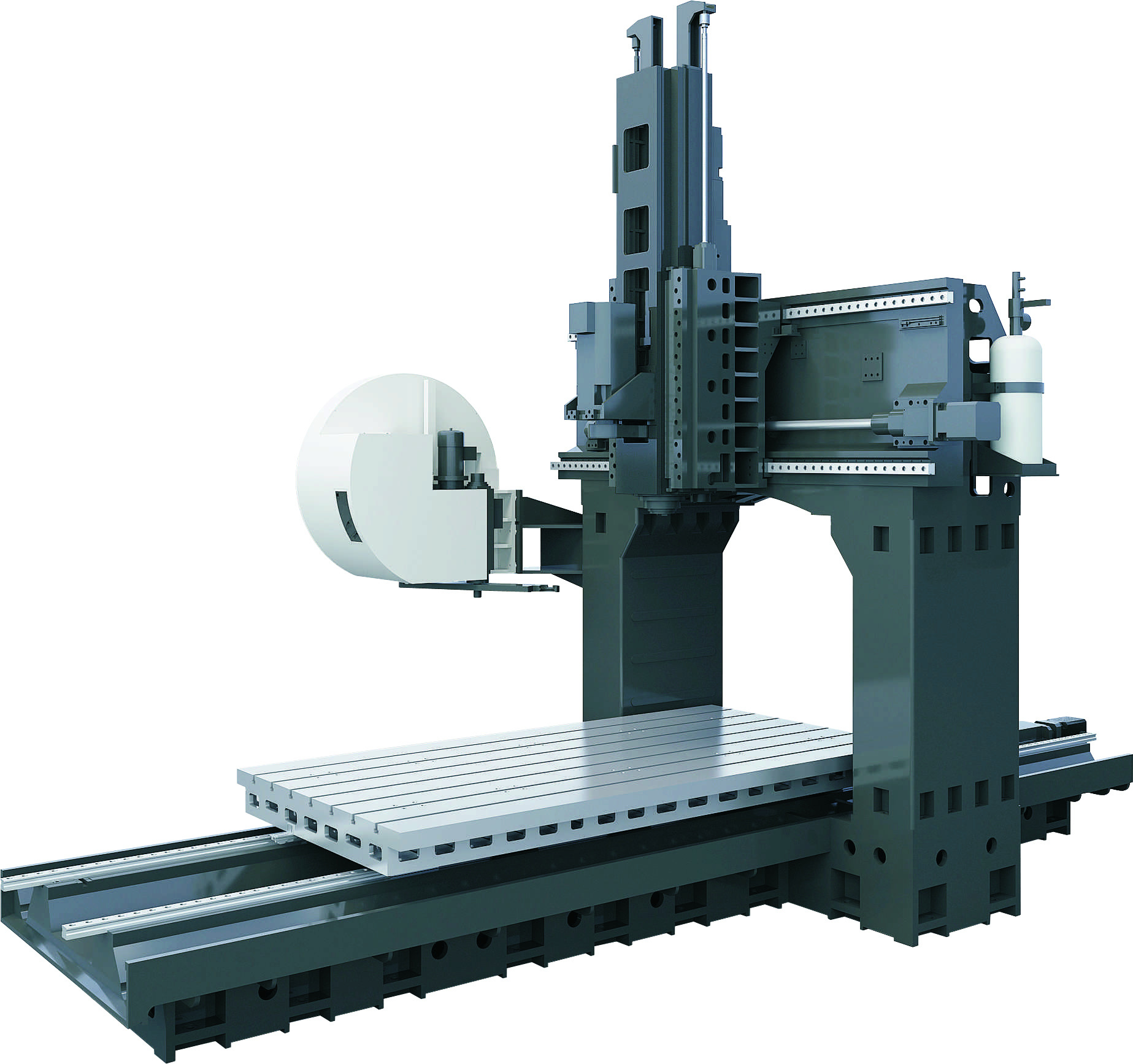

1. The rigidity of the whole machine exceeds the vertical acceleration!

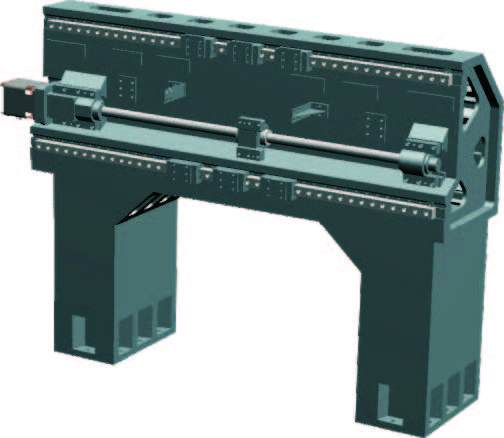

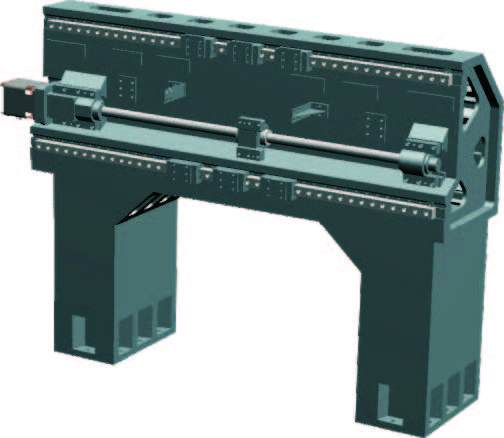

〇 Integrated beam and column composite

2. The best structural strength!

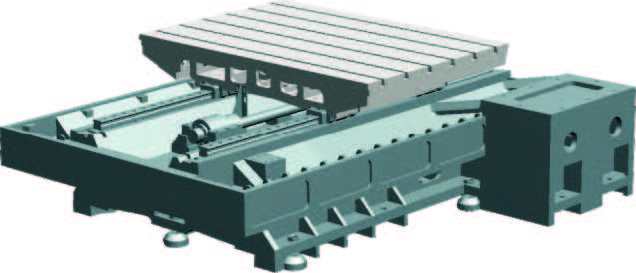

3. The machining accuracy of the fully supported worktable is more stable!

4. The best feeding system!

The preferred product for upgrading of medium-sized Riga is "strong debut"

1. The rigidity of the whole machine exceeds 2 times of vertical plus!

〇The machine tool adopts a door structure, and the double columns and

The door back structure of cross beam combination makes the whole machine more rigid and stable

High rigidity, heavy cutting, high speed and high precision;Integrated beam and column composite

Optimize the original six pieces of the gantry into five pieces to avoid assembly

Error, and improve the stability of the whole machine.

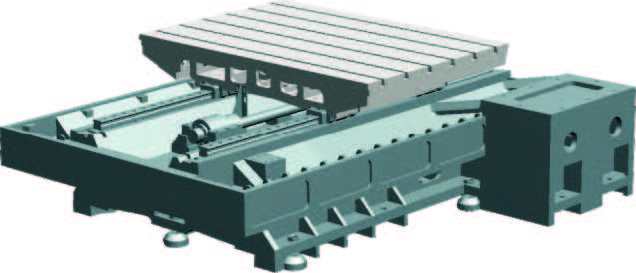

The machining accuracy of the fully supported worktable is more stable!

〇The worktable runs 100% completely on the supporting surface,

Ensure the uniform friction coefficient during the movement of the workbench,

Achieve high stability, long service life and heavy load of the machine tool.

〇 The workbench passes through the middle of the column, its width and Y-direction stroke increase by 25%, making the space utilization in Y-direction more effective,

It is beneficial to the processing of round and square parts such as moulds and boxes.

Users can choose the auxiliary workbench design to facilitate users' clamping and use, and improve the rigidity and accuracy of gantry machine toolsThe best feeding system!

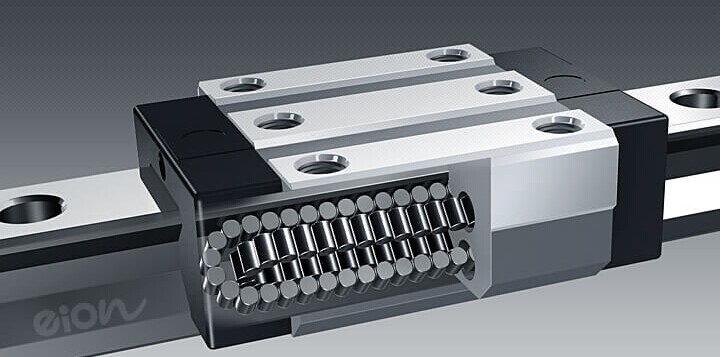

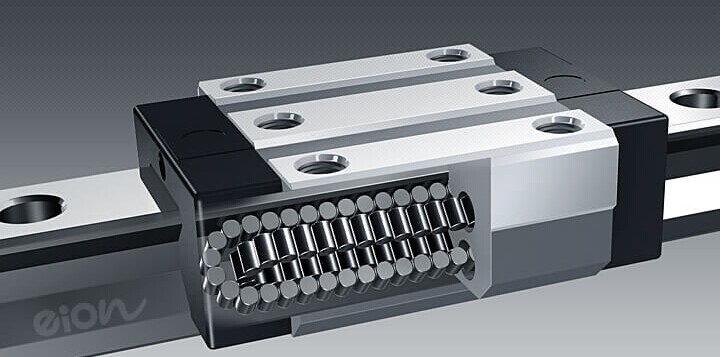

Axis X and Y adopt linear heavy-duty roller guide rail with low friction coefficient, which improves the positioning accuracy and dynamic accuracy of the drive;

Superior performance lies in the design of each fuselage component

Each component has been repeatedly designed and calculated to achieve excellent structural rigidity, and has been manufactured and verified for many times to finally obtain the requirements of the processor for rigidity and accuracy, and meet the vast majority of user use scenarios.

High precision moving parts ensure high machining accuracy

All lead screws and wire rails are made of Taiwan Shangyin/Yintai or above brands, and fake or low-grade functional parts are rejected. The three-axis lead screw bearings are made of Japanese NSK high-precision bearings

The dustproof treatment prevents the iron filings from entering. Only high-quality functional parts can achieve good quality.

Details determine success or failure, practical, reliable and beautiful

Every detail has been carefully designed by technicians to meet the needs of use and to be beautiful. The assembly personnel will strive to make every detail perfect

Specifications(Unit in brackets)

Travel

Left and right X axis - 6200 (mm), front and rear Y axis - 4000 (mm), upper and lower Z axis - 1250 (mm);

workbench

Size: - 6000x2600 (mm), maximum bearing: - 18000 (kg), distance from workbench to spindle end face: - 350 to 1600 (mm);

Feed drive

G01 feed speed 10 (m/min), G00 fast moving speed - 10 (m/min);

Spindle

Spindle taper BT50, spindle speed 6000 (rpm), spindle motor 22/26 (kw),

Triaxial

accuracy Positioning accuracy 0.02, repeated positioning accuracy 0.015 Tool magazine

Robot tool magazine 24 (pcs), tool change time 1.8 (s), maximum tool length 300 (mm), maximum tool diameter 78 (mm), maximum tool diameter 120 (mm), maximum tool weight 8 (kg);

other

product details

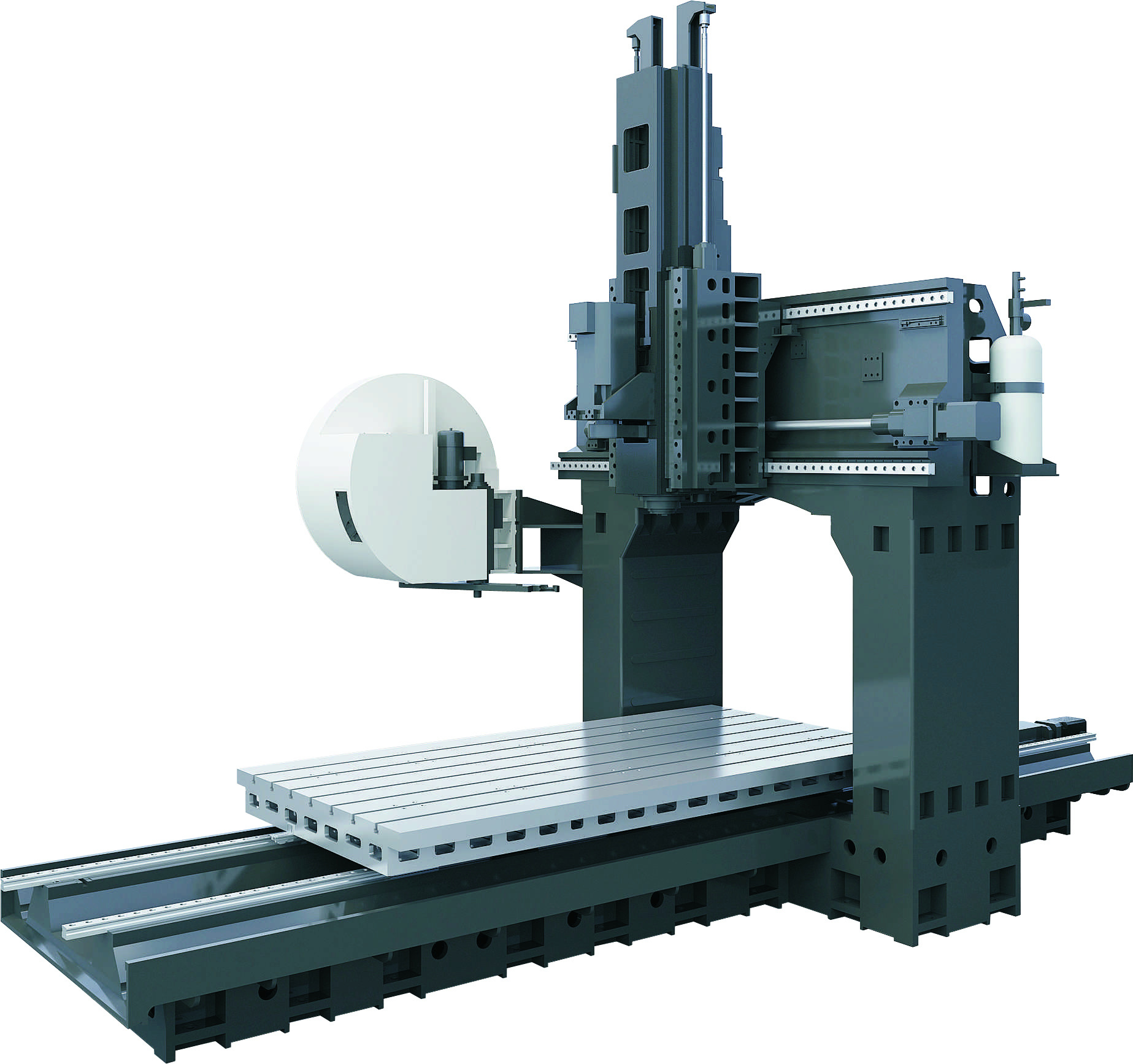

GL3460 high rigid gantry machining center

1. The rigidity of the whole machine exceeds the vertical acceleration!

〇 Integrated beam and column composite

2. The best structural strength!

3. The machining accuracy of the fully supported worktable is more stable!

4. The best feeding system!

The preferred product for upgrading of medium-sized Riga is "strong debut"

The rigidity of the whole machine exceeds 2 times of vertical plus!

〇 The machine tool adopts a door structure. The door back structure of double columns and crossbeams is carefully designed. The rigidity of the whole machine is more stable, with high rigidity, heavy cutting, high speed and high precision;

Integrated beam and column composite

The original six parts of the gantry are optimized into five parts to avoid assembly errors and improve the stability of the whole machine.

The machining accuracy of the fully supported worktable is more stable!

〇 The worktable runs 100% completely on the supporting surface,

Ensure the uniform friction coefficient during the movement of the workbench,

Achieve high stability, long service life and heavy load of the machine tool.

The worktable passes through the middle of the column, and its width and Y-direction stroke increase by 25%, making the space utilization in Y-direction more effective, which is conducive to the processing of round and square parts such as molds and boxes.

Users can choose the auxiliary workbench design to facilitate users' clamping and use, and improve the rigidity and accuracy of gantry machine tools

The best feeding system!

Axis X and Y adopt linear heavy-duty roller guide rail with low friction coefficient, which improves the positioning accuracy and dynamic accuracy of the drive;

Superior performance lies in the design of each fuselage component

Each component has been repeatedly designed and calculated to achieve excellent structural rigidity, and has been manufactured and verified for many times to finally obtain the requirements of the processor for rigidity and accuracy, and meet the vast majority of user use scenarios.

High precision moving parts ensure high machining accuracy

All lead screws and wire rails are made of Taiwan Shangyin/Yintai or above brands, and fake or low-grade functional parts are rejected. The three-axis lead screw bearings are made of Japanese NSK high-precision bearings

The dustproof treatment prevents the iron filings from entering. Only high-quality functional parts can achieve good quality.

Details determine success or failure, practical, reliable and beautiful

Every detail has been carefully designed by technicians to meet the needs of use and to be beautiful. The assembly personnel will strive to make every detail perfect

Product message

产品卖点

数控系统

选用日本数控系统FANUC Series 0i - MODEL F PLUS, 正规供货渠道,绝非低价异常渠道,绝非翻新机,无售后的后顾之忧

丝杆轴承

选用日本NSK品牌正品保证,假1赔10选用闭式带防尘盖结构,杜绝铁屑进入滑道。 骏宇所选用的均为闭式(自带防尘盖)NSK轴承,价格比开式轴承贵约30%,故障率可降低约90%。

主轴

选用台湾品牌的成套主轴 锥孔规格:BT40 主轴套筒外径:150mm 最高转速:8000/10000/12000rpm (可选择)

刀库

选用日本NSK品牌正品保证,假选用市场占有率高的品牌 规格:BT40 刀具数量:24把 伺服控制方式1赔10选用闭式带防尘盖结构,杜绝铁屑进入滑道。 骏宇所选用的均为闭式(自带防尘盖)NSK轴承,价格比开式轴承贵约30%,故障率可降低约90%。

丝杆和线轨

选用台湾上银/银泰品牌以上的丝杆和线轨 丝杆:直径40mm,螺距16mm, 精度等级C3级,市场上有用C5级丝杆,价格相差约10%,用户需留意 线轨:XY轴宽度35mm,滚柱形式,Z轴宽度45mm,6滑块,滚柱形式, 精度等级P级,市场上有用H级丝杆,价格相差约10%,用户需留意

Related products

Additional notes:

Bed: high-grade cast iron, treated with long-term natural aging.

Column: A wide column structure is adopted to ensure that the machine tool still has good rigidity when heavy cutting.

Spindle: NSK angular contact bearings (outer diameter 120mm) are selected to ensure strong and smooth cutting over the entire speed range.

Guide rail: Linear rolling guide rail is adopted.

Rigidity: The spindle has a high rigid structure and can be used for high-precision heavy cutting processing.

Ball screw: high-precision ball screw (lead screw diameter 32mm), using pre-stretched structure, so that the three axes have good dynamic rigidity and resistance to thermal deformation.

Tool magazine: using the tool arm type tool magazine, the tool selection method is arbitrary in both directions, and automatically threatens the next tool change to provide the nearest path, less non-cutting time.

User reviews

We are a manufacturer of auto and engineering machinery parts. In recent years, we have purchased many equipment from Datian CNC, including: forced cutting machine MD855, horizontal heater HL-800, vertical horizontal composite WHRW1200, etc. In general, the impression of Datian CNC is that the product processing efficiency is relatively high, especially the vertical and horizontal composite machine tools, which combine the vertical and horizontal machining centers on the same machine tool to solve the problem of secondary clamping, greatly improving our processing efficiency, reducing the number of machine tools, the number of products in process, the floor area and the labor demand. Datian CNC has always been our long-term strategic partner to achieve the optimal transformation from technology to productivity.

|

|

|

Hefei Tian* Precision Casting Co., Ltd

Workshop director: Li

WHRW630

Hefei Tian* Precision Casting Co., Ltd

WHRW630

Workshop director: Li

Datan CNC's main products or services: high-speed and high-precision machining center, five-axis Simultaneously controllable machining center, functional complex machining center, flexible manufacturing units, Hardware, software and service providers for R&D and production of high-end and mid-to-high-end CNC machine tools.

Contact Details

E-mail:slash@hzdtsk.com

Address: Lin Pu high tech Development zone of xiaoshan District of Hangzhou city in Zhejiang province China