Action description of fixed cycle

Release time:

2022-11-17 18:50

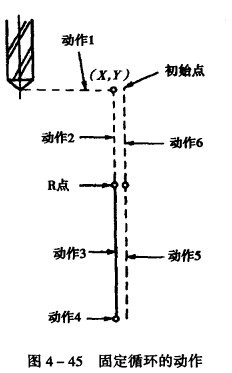

The hole machining fixed cycle usually consists of the following 6 actions.

Action 1 - Positioning of X axis and Y axis, the tool is quickly positioned above the hole processing position.

Action 2 - Fast forward to the R point, and the tool is fast fed from the initial point to the R point (the position ready for cutting)

Action 3 - Hole machining, which executes the action of hole machining in cutting feed mode.

Action 4 - Actions at the bottom of the hole, including pause, spindle stop, tool shift, etc.

Action 5 - Return to the R point and continue the hole processing in the next step.

Action 6 - Quickly return to the initial point. After the hole processing is completed, the initial point should generally be selected.

The action of fixed cycle is shown in Fig. 4-45. The dotted line in the figure represents the rapid feed. The solid line represents the cutting feed.

1. Initial plane

The initial plane is a plane specified for safe feed cutting. The distance from the initial plane to the part surface can be arbitrarily set at a safe height. When the same tool is used to process several holes, G98 can be used only when there are obstacles between the holes that need to jump or when all holes are processed, so that the tool returns to the initial point on the initial plane.

2. Reference plane

The reference plane is also called the R point plane. This plane is the height plane from fast forward to tool feed when the tool is cutting The distance from the workpiece surface mainly considers the change of the workpiece surface size, generally 2-5mm. When using G99, the tool will return to the R point of the plane.

3. Hole bottom plane

When machining blind holes, the bottom plane of the hole is the Z-axis height of the hole bottom. When machining through holes, the tool will generally extend a distance beyond the bottom plane of the workpiece, mainly to ensure that all hole depths are processed to size. When drilling, the influence of the drill tip on the hole depth should also be considered. The positioning plane is determined by the plane selection code G17, G18 or C19.

Related news

Datan CNC's main products or services: high-speed and high-precision machining center, five-axis Simultaneously controllable machining center, functional complex machining center, flexible manufacturing units, Hardware, software and service providers for R&D and production of high-end and mid-to-high-end CNC machine tools.

Contact Details

E-mail:slash@hzdtsk.com

Address: Lin Pu high tech Development zone of xiaoshan District of Hangzhou city in Zhejiang province China