Detailed explanation of arc swing fine grinding and polishing machine JP15.4

Release time:

2022-11-01 11:02

The following takes JP15.4 arc swing polishing machine as an example to introduce its application characteristics, main technical performance and general layout in detail. Please refer to www.hzdtsk.com/about22/1.html for more and better information about arc pendulum polishing machine.

1、 Purpose and characteristics of machine tool

JP15.4 arc swing fine grinding and polishing machine is mainly used for fine grinding and polishing medium-sized spherical optical parts. In order to get used to the requirements of various speeds in fine grinding and polishing, the machine tool is equipped with a spindle gearbox. The rocker arm swings around the center of the ball to finish the precision grinding and polishing of the quasi center of the ball, so that the precision grinding and polishing process adhere to stable pressure. The machine tool is controlled by a clock, which can complete the processing of punctuality, fixed aperture and defect detection. Therefore, the machine tool has high production rate and convenient operation, The machine tool has four rocker arms that can swing synchronously and adjust the swing position separately.

2、 Main technical performance of the machine tool

Maximum radius of curvature of fine grinding and polishing R50MM

Spindle speed 240 467 714R/MIN

Swing speed of pendulum shaft 28 times/min

Maximum swing 45 degrees

Working pressure 0-100N

Total motor power 0.67KW

3、 General layout of the machine tool

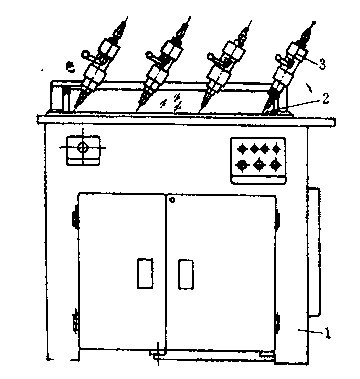

Figure 4-8 shows the general layout of JP 15.4 arc swing finishing polishing machine It is mainly composed of box, main shaft swing arm and servo head, linkage, cooling device, electrical system and other components

The transmission unit is located on the inner bottom plate of the gearbox Cast iron water basin 2 is placed above the box, the gearbox, bridge frame, and the main shaft assembly is installed in four equidistant holes of the water basin. Each pendulum shaft is installed on the roll bearing seat at the upper rear of the box, on which the swing arm and pressure head are fixed. 3. Polishing liquid or coolant cylinder, heater. The mercury thermometer is placed on the left side of the box cavity, and the electrical device is on the right side

Related news

Datan CNC's main products or services: high-speed and high-precision machining center, five-axis Simultaneously controllable machining center, functional complex machining center, flexible manufacturing units, Hardware, software and service providers for R&D and production of high-end and mid-to-high-end CNC machine tools.

Contact Details

E-mail:slash@hzdtsk.com

Address: Lin Pu high tech Development zone of xiaoshan District of Hangzhou city in Zhejiang province China